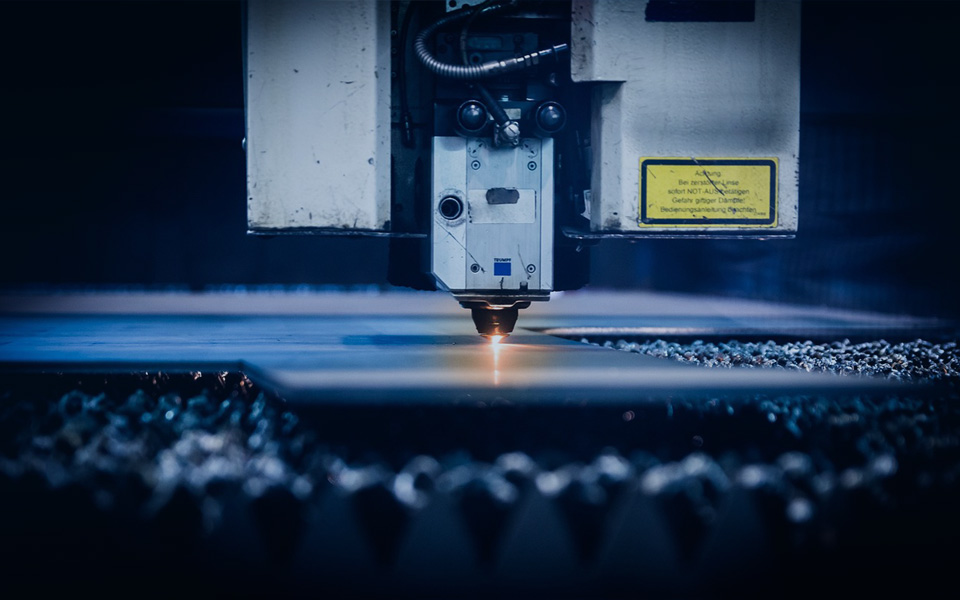

Equipment function

The optical path of the laser transmitter of the hard optical path welding machine is direct output, which requires low professional skills for maintenance, It is widely used in mold repair welding, welding of thermos cup, cup handle, towel rack, metal switch panel, door lock and hinge hardware,The weld is smooth and beautiful, and automatic welding can be realized through PC control.

1. The hard optical path laser welding machine adopts "current feedback technology" and uses the shutter to filter the unstable spot to enhance the welding stability;

2. Integrated optical path output, simpler optical path maintenance and less optical transmission loss;

3. It can switch energy in real time and automatically switch waveforms for different welding processes;

4. It can be connected with automation equipment remotely and easily;

5. The solder joint is full and smooth, the welding strength is close to the base metal, and only simple treatment or surface treatment is required after welding;

6. The depth width ratio of the welding spot is high, the weld width is small, the heat affected zone is small, the deformation is small, and the welding speed is fast.

| Model | ST-T150w | ST-T300w | ST-T400w |

| Laser wavelength | 1064nm | ||

| Maximum output power | 200w | 300w | 500w |

| Maximum pulse energy | 60j | 90j | 100j |

| Maximum peak power | 6kw | 10kw | 10kw |

| Pulse repetition rate | 1-100kz | 1-200HZ | 1-200HZ |

| Pulse width | 0.1-20ms | ||

| Number of separable light | Route 1-2 | ||

| Laser working medium | Nd:YAG | ||

| Aiming and positioning | Red light (optional with CCD) | ||

| Fiber type | Optical path direct output | ||

| Cooling mode | water-cooling | ||

| Closed loop feedback control mode | Arbitrary waveform real-time control current feedback | ||

| Energy fluctuation | <±3% | ||

| Power requirements | AC380V±10% 5060hz | ||

| Device power consumption | 8kw | 12kw | 18kw |

Dongguan Chuangde Laser Intelligent Technology Co., Ltd

One stop laser welding solution service provider