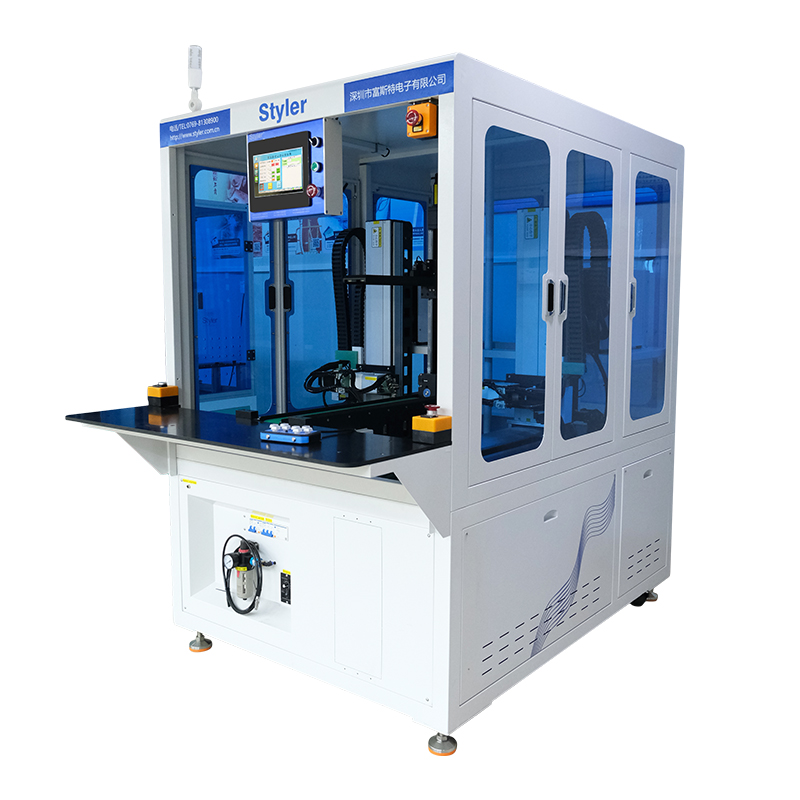

New semi-automatic double-sided spot welding machine

Equipment features

The double headed horizontal automatic spot welding equipment is an automated device developed specifically for welding direction consistency and improving efficiency by using double-sided simultaneous welding;

The double head horizontal automatic spot welding equipment can accommodate battery packs with a maximum size of 600 X 500 mm and a height of 60-70mm;

The equipment adopts functions such as welding needle compensation, left and right independent four group energy switching, welding needle repair, welding needle polishing alarm, welding or asymmetric welding when left and right are wrong to ensure welding stability;

The equipment adopts measures such as electromagnetic adsorption, material in place detection, cylinder compression, servo control, etc. to improve the accuracy of welding positions;

The device can quickly switch products with inconsistent welding directions through a clamp that can quickly switch 90 ° welding directions;

The device achieves foolproof operation through measures such as operating the joystick, CAD mapping, multiple array calculations, sharing data with USB drives, local operations, touch screen rotation, Z-axis forward and backward movement, breakpoint virtual welding, and automatic detection of material startup;

The device is equipped with a lock screen function to prevent accidental operation.